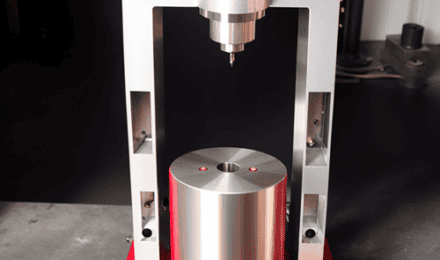

The four-column hydraulic press is one of the main energy-consuming equipment. So reducing the energy consumption of these press has become a factor in reducing costs. It is also an effective way to improve product competitiveness.

Energy-saving and environmental protection: how to reduce its own power consumption from the four-column hydraulic press

-

Frequency Conversion Energy-Saving Principle

The power consumption of the four-column hydraulic press reflects in the power consumption of the hydraulic system oil pump.

The power consumption of the hydraulic oil pump accounts for more than 97% of the entire hydraulic machine. So reducing its power consumption is the key to energy saving of the hydraulic machine. The pressure and flow required by the hydraulic press change in the stages of fast descending, slow descending, pressure holding, pressure relief return, piston ejection, piston retraction, buffer cylinder ejection, etc.

When the oil demand of the hydraulic press changes, the relief valve at the oil pump outlets adjusts the load pressure and flow. The output power of the motor remains unchanged, thus causing energy waste.

The frequency conversion speed control device has a rectifier circuit, a filter circuit, an inverter circuit, and a control circuit. Its function is to rectify and filter the AC power into DC power through the rectifier link. It then converts it into AC power with different frequencies through the inverter link.

Therefore, the hydraulic oil pump motor can work at different speeds. In addition, according to the theory of the oil pump, the calculation formula of the output flow Q of the oil pump is:

Q=2[π(R2-r2)-(R-r)S×Z/COSθ]B×N10-6

In the formula: R – the radius of the blade r – the short radius of the stator

S-the thickness of the blade B-the axial width of the rotor

Z – number of blades θ – inclination of blades relative to the radial direction

From the above formula, changing the rotational speed N of the oil pump motor rotor also changes the output flow Q. That is, the oil pump oil flow is proportional to the rotational speed of the oil pump motor. Changing the rotational speed N of the oil pump motor rotor is automatically controlled by the synchronizing signal of the hydraulic press.

It is realized by the output frequency of the variable frequency energy-saving speed control device. The power consumption of the oil pump motor is approximately in a cubic relationship with its speed. That is, the power consumption of the oil pump motor is P=P'(N’/N)3.

If the rated power of the hydraulic oil pump motor is 55KW, then when the speed drops to 4/5 of the original speed, its power consumption is 28.16KW, saving 48.8% of power; when the speed drops to 1/2 of the original speed, its power consumption is only 6.875KW, saving power Electricity 87.5%, so that the oil pump load has an obvious power-saving effect (among them: P’=55KW, N’/N=4/5 and N’/N=1/2).