The Large-scale free forging hydraulic press is an indispensable piece of equipment in the machinery manufacturing industry. Large-scale free forgings and large-scale die forgings must be used in large-scale machinery and equipment production in many industries. Some of these industries includes aviation, shipbuilding, petroleum, chemical, steel rolling, and military industries. These large forgings uses large free forging hydraulic presses and large die forging hydraulic presses to forge. Therefore, the quantity, variety, grade, and quality of forging equipment owned by a country matters. It can be the standards to measure its industrial level and national defense strength.

Application of Y13 Series Free Forging Hydraulic Press

Y13 series of free forging hydraulic presses are large-scale free forging equipment, divided into ordinary free forging hydraulic presses and special hydraulic presses for ring rolling.

The ordinary free forging hydraulic press is suitable for the free forging of metallic materials and metal membranes. It has the functions of fast forging, constant forging, and pressure holding. It also meets the forging process requirements of upsetting, drawing, punching, reaming, bending, and shifting.

The professional hydraulic press for ring rolling has an automatic blank centering device and a swing arm punch device. Therefore, it can quickly complete the upsetting and punching of materials. The machine works great in conjunction with a CNC radial and axial ring-rolling machine.

Main Features Of Y13 Series Free Forging Hydraulic Press:

- Intelligent PLC operation control system, touch screen man-machine dialogue interface.

- Indoor remote control operation, low labor intensity, and good working environment.

- Convenient and quick to change the mold device to improve production efficiency.

- Practical multi-point, multi-stage pressure relief system improves the stability of the equipment.

Design Advantages Of Y13 Series Free Forging Hydraulic Press

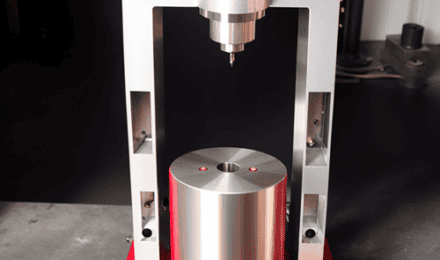

- The hydraulic system adopts a two-way cartridge valve integrated control system. The oil inlet and outlet adopt a two-stage control method. The main cylinder and system pipeline unloading adopt three-stage hydraulic and electrical high-speed unloading (time is 0.3s only) so that the hydraulic press. The action is fast, smooth, and without vibration.

- The quick-change anvil-changing device adopts the T-slot hanging method, which can change different upper anvil blocks.

- The replenishment system of the free forging hydraulic press adopts a large replenishment tank and a zero-pressure replenishment method in the oil tank with a large filling valve, which has the advantages of rapid and sufficient replenishment, safety, and no leakage.

- The movable beam guide of this equipment and the oil cylinder’s guide length are long. Therefore plunger and the sliding block connects by a ball head. This creates the advantages of strong anti-eccentric load ability and machine protection.

- This equipment also adopts dual control of position and pressure.

- All control valve blocks are placed on the fuel tank with a low maintenance position, which is convenient and safe for maintenance.

- The connection of the main plunger and the movable beam, the rebound plunger, and the lifting beam are all connected by ball joints, which effectively solve the problem of an unbalanced load.

- Oil temperature, liquid level, cooling detection, alarm devices, and hydraulic system pressure detection devices are installed to detect and protect the machine in many aspects.