Description

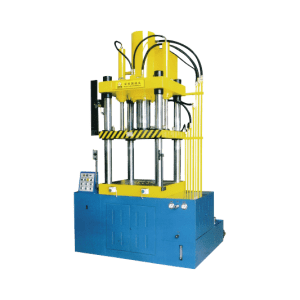

Multi-Purpose Hydraulic Press LY32 Series

As the name suggests, the LY32 series is designed for multiple applications in hydraulic processes. In addition to that, this series offers absolute durability due to the quality materials and technology used. The performance and productivity of the LY32 series is unrivaled.

Product Features:

-

- The standard configuration is a two-way dual-pressure plug-in integrated system provided by Italian ATOS.

- The whole series is equipped with a friendly man-machine touch exchange intelligent interface, a perfect imported electrical appliance programming control system, with fault detection and display.

- Supports the linking of automated peripheral devices

- The optimized design of the machine produces fast function, fast approach, slow form, and fast return.

- The four-column guided bottom cylinder structure used to meet the professional metal sheet drawing process, and the blank holder force can be adjusted remotely.

- The whole series adopts 40Cr alloy round steel, high-standard four-pillar structure with quenched and tempered, medium frequency, and hard chrome plating.

- The movable beam plate adopts welded structural parts and cooperates with the composite guide belt, which has high guide accuracy and stronger lateral resistance.

- Adopt high-quality forged, precision-processed oil cylinder body and pistons with heat treated hard chrome plating.

- The design of hydraulic oil multi-stage precision filtration and full-time cooling system offers stable performance for long-term work.

- Advantageous seal control design, made using imported high and low pressure combined seal combination.

- The whole series of the whole machine is optimized by finite element analysis and design and has a unique “sub” welded reinforced seismic base. So, so foundation treatment is required.